Pihl Excavating reduces onsite time by at least 50% with digital construction monitoring solution

Pihl Excavating is an Oregon-based, earthmovingEarthmoving refers to the process of moving large amounts of earth or soil using heavy machinery such as excavators, bul… More enterprise dedicated to high quality workmanship. What began in 1996 as a small logging and excavation company, is now an expanding enterprise with over 80 employees and a heavy equipment fleet tailored to meet the changing demands of today’s fast-paced construction projects. As part of this commitment and to help streamline and optimize processes, Pihl is adopting digital constructionDigital construction, also known as construction technology or construction 4.0, refers to the use of digital tools and … More technologies on multiple projects.

Main benefits

80% in time savings

70% increase in collaboration

60% increase in accuracy of estimation

Background

Pihl Excavating is an Oregon-based, earthmovingEarthmoving refers to the process of moving large amounts of earth or soil using heavy machinery such as excavators, bul… More enterprise dedicated to high quality workmanship. What began in 1996 as a small logging and excavation company, is now an expanding enterprise with over 80 employees and a heavy equipment fleet tailored to meet the changing demands of today’s fast-paced construction projects.

Today, the company focuses on excavation and grading services for commercial developments, vineyards and wineries, reservoirs, and land clearing projects. Its team approaches every project with commitment and professionalism, and as a result, has established an excellent reputation in the industry.

As part of this commitment and to help streamline and optimize processes, Pihl is adopting digital constructionDigital construction, also known as construction technology or construction 4.0, refers to the use of digital tools and … More technologies. These include DatuBIM – Datumate’s cloud-native SaaS 4D infrastructure data analytics platform – which Pihl started using just over a year ago on multiple and diverse projects.

Aron James

Grade Control Manager at Pihl Excavating

Planning and constructing a storm retention pond at Hampton Lumber Mill

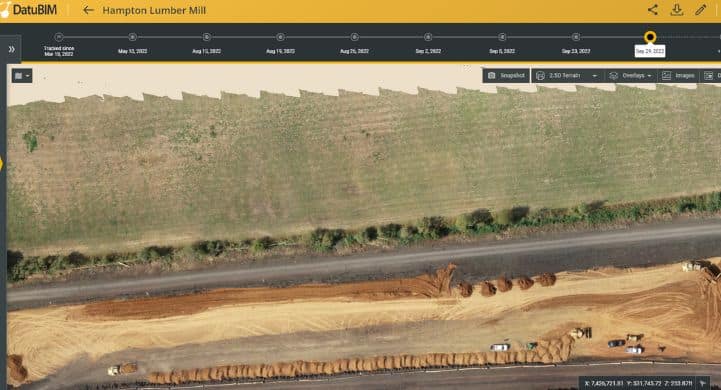

One such project is a storm retention system and pond at the Hampton Lumber Mill in Willamina, Oregon, which is being built to replace an existing pond on the other side of the mill to pump all storm runoff.

The project began in mid-August 2022 and comprises two phases. The first phase, which involved the preparation of the pond, excavation and removal of materials, is now complete. To date, approximately 10K cubic yards of material has been excavated and removed. The second phase, which includes the running of the storm line and pipe utility installation will begin soon.

Projects involving both excavation and utility installation come with multiple challenges:

- Difficulty in accurately estimating the amount of earth that needs to be moved, especially when there is water involved

- Finding skilled and qualified operators for all stages of the project

- Amount of time and resources needed for onsite visits and supervision during the project

The goal of this project is to relieve congestion and improve vehicle, pedestrian, bike and family safety in the neighborhood while maintaining the road’s residential character. This is being done by turning the road from a two-lane into a three-lane roadway; adding a new center turn lane, curbs, gutters and sidewalks; increasing access to local driveways; eliminating roadside ditches; improving drainage; and adding bike lines in both directions.

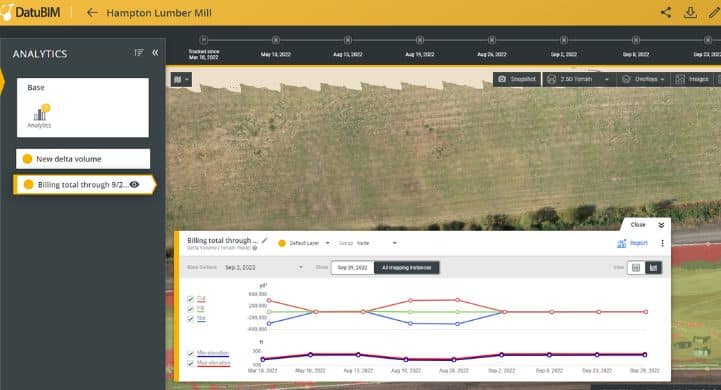

Drone images and analytics help provide more accurate estimations for bidding phase

Aron James, a grade control manager at Pihl and a registered drone pilot, already started using the DatuBIM platform during the estimation stage of the Hampton Lumber Mill project in March 2022. Initially, he flew a drone to capture and track cubic yards of materials that would need to be extracted for the new pond, processed these images using the platform, and then sent the information to the company’s estimators so they could calculate volumes and put numbers to them. This enabled the company to create a more accurate bid for the project, which they then won.

A quick and easy ramp-up and transition to data analytics and monitoring

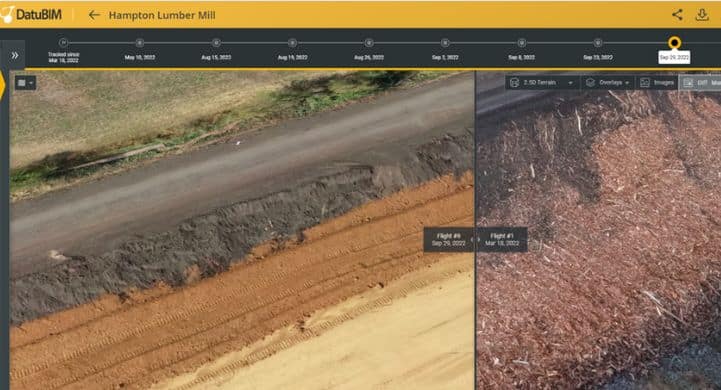

The actual project began in mid-August and since then, James and his team have been using DatuBIM extensively to track progress and measure the amount of material extracted and removed; and compare design to Digital As-Builts to detect any deviations. In addition to James, there are another two in-house pilots at Pihl, all of whom are using a Phantom 4 RTK drone to get accurate images of worksites.

“I introduced the platform to my project managers who are now able to track all the material on their own,” says James. It’s super easy to teach them how to use it and they can just jump in and track the moving of dirt themselves. It’s really great because on this job, we sometimes have as many as 15 dump trucks a day hauling material out. So instead of those guys trying to track all that in the field, we fly the drone about once every week or two and we can track all that material automatically and remotely.”

Cutting down 50% of time spent onsite

In Oregon, it’s not unusual to drive long distances from job to job. In fact, prior to using DatuBIM, the team at Pihl often had to drive hundreds of miles every week visiting worksites and carrying out foot topos of the terrain to calculate stockpile volumesStockpile volumes, in the context of construction or earthworks, refer to the measurement and quantification of the mate… More and check progress. In addition to being extremely time-consuming, this also posed physical and safety risks.

In the case of the Hampton Lumber Mill project, it takes James about an hour and a half each way, which totals in a half day of work. With Datumate, he can send another drone pilot to the site while he works on other things in the office. So instead of spending so much time onsite, he is only spending 15-30 minutes on processing the information he receives.

“I’ve been down there about 10 times since we started working on the project,” he explains. “I estimate that I would have at least doubled that (20 or more times) if we weren’t using Datumate. In addition to the amount of time this would have consumed, it also would have delayed the project itself as I am extremely busy at the moment.”

Additional benefits

According to James, there are also other major benefits that come with using DatuBIM. These include:

Easy to use and to teach

James says he has used a few different platforms and Datumate is tenfold so much easier to use and easier to teach.

Streamlines team collaboration and communication

Reports are used in status meetings and relevant information is sent to project managers and estimators throughout the project lifecycle.

Photo documentation and easy progress tracking

“This makes it really easy to see and share in meetings,” says James. “I’m not just telling people you have this much material. Instead, I can switch through the dates and it makes it so much easier for people to see and put a number to a visual.”

Accurate billing

In projects like these, especially when the ground is wet, it’s difficult to accurately estimate the amount of earth that will need to be moved. In this case, once the bid amount of earthwork was extracted and the team needed to extract more, they could accurately measure the additional material and charge for it.

Added value

- Saves significant amount of time in site visits

- Streamlines team collaboration and communication

- Provides accurate estimations for bidding process

- Enables accurate estimating and billing of earth moved and materials

What's next?

Pihl is currently about halfway through the Hampton Lumber Mill project and is now entering the second phase, which involves the pipe utility installation. Once they start getting the pipe in the ground, James is planning to periodically created As-Builts to show the project owner how much pipe has been installed and where it is located. In addition, the platform is already being used to measure elevations and calculate cut and fill before the pipe laying, and to detect any potential deviations between the design and the actual site conditions and more easily resolve them.

Stay tuned to learn about additional Pihl Excavating projects that benefit from digital constructionDigital construction, also known as construction technology or construction 4.0, refers to the use of digital tools and … Moreconstruction data analyticsConstruction data analytics involves using data to gain insights and make informed decisions related to construction pro… More and monitoring.